Reverse Engineering |

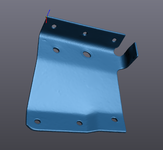

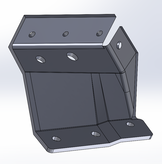

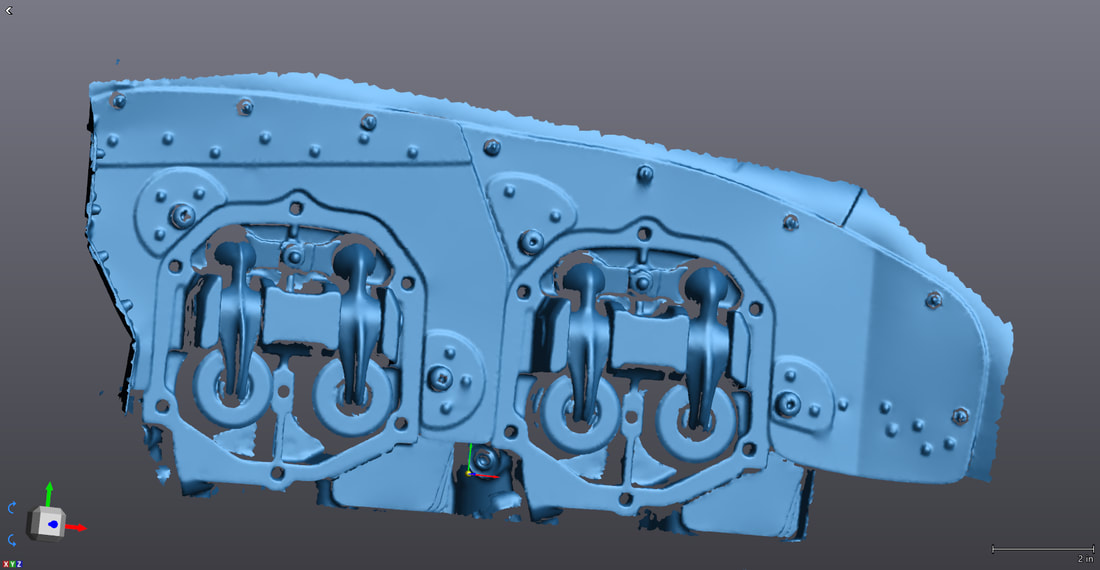

Reverse engineering is the process of reproducing a part to its exact dimensions, and 3D scanning is the ultimate tool for it. Our 3D scanner is accurate to 0.0016" so we can produce near exact scans. Reverse engineering is great for remaking parts that may no longer be in production or may be extremely hard to find. The images to the left are an example of a critical piece belonging to the tail section of a variety of different aircraft. This piece has been found to be weak and can result in a deadly situation if it

|

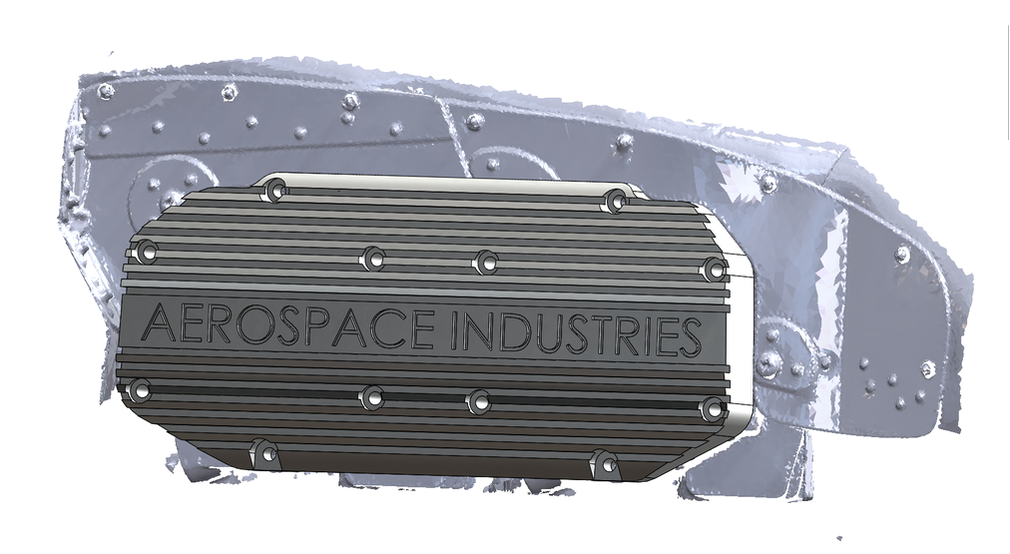

fails. This is not acceptable under any circumstances so we were asked to 3D scan the original piece, reverse engineer it, and redesign it to be significantly stronger. The first image is the original piece, second is the scan, and third is the modified design which will be CNC machined using billet aluminum. During the process we were also able to 3D print prototypes to test fit to guarantee fitment prior to machining. This process is several times more difficult with out this technology and it ends up taking more time and money to do with out our services. Even if this gear was broken and we only were given a chunk we can easily repair the gear in our software to CNC machine a new one! The applications for reverse engineering are endless, so if you have any parts you need re-manufactured, redesigned, or CNC machined out of a better material, our 3D scanning and reverse engineering services are for you!

Product design |

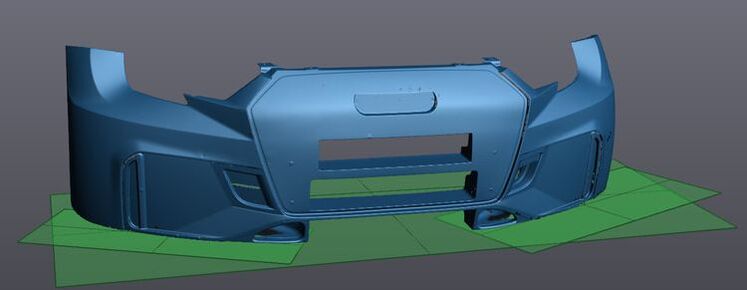

3D scanning is the perfect tool for product design when it comes to designing a product which needs to be compatible with something that already sexists. This is how we were able to design both our Aircraft interiors as well as our engine components. We can easily guarantee fitment and take measurements accurate to 0.0016 inches without ever physically measuring the part. This make creating new products extremely efficient and quick. The amount of time saved

|

from having to measure everything by hand is massive, and it also eliminates that human error. Using the scans its easily to design around what ever was scanned, and it also makes it possible to very easily make changes to existing products. We can quickly scan the product and very easily make any desired changes to the design in out CAD software.